In the world of packaging, the right tools can make all the difference. Whether you’re packaging food, pharmaceuticals, or other products, a bag sealer machine is a crucial piece of equipment. It ensures that your products are securely sealed, maintaining their freshness, integrity, and shelf life. However, with so many options available, choosing the right bag sealer machine can be overwhelming. This comprehensive guide will walk you through everything you need to know to make an informed decision.

From understanding the benefits of bag sealer machines to exploring the different types, sealing methods, and key factors to consider, we’ll cover it all. By the end of this guide, you’ll be equipped with the knowledge to select the best bag sealer machine that fits your needs, budget, and production requirements. So, let’s dive in and streamline your packaging process with the perfect bag sealer machine.

Benefits of Using Bag Sealer Machines

1. Enhanced Product Freshness and Longevity

One of the primary benefits of using a bag sealer machine is its ability to maintain product freshness. By creating a secure seal, these machines prevent air, moisture, and contaminants from entering the packaging, thus preserving the quality and extending the shelf life of your products. This is particularly important for food items, which are prone to spoilage if not properly sealed.

2. Improved Packaging Efficiency

Bag sealer machines significantly improve the efficiency of your packaging process. Whether you’re sealing a small batch or a large volume of products, these machines provide consistent, high-quality seals quickly and effortlessly. This not only saves time but also reduces labor costs, as the process is automated and requires minimal manual intervention.

3. Professional-Looking Packaging

A well-sealed package reflects professionalism and attention to detail. Bag sealer machines ensure that your packaging looks neat and consistent, which is crucial for brand reputation. A professional appearance can make a significant difference in consumer perception, influencing purchasing decisions and building brand loyalty.

4. Cost-Effective Solution

Investing in a bag sealer machine can be a cost-effective solution in the long run. By reducing product wastage due to spoilage and improving packaging efficiency, these machines can save you money over time. Additionally, automated sealing reduces the need for manual labor, further lowering operational costs.

5. Versatility

Bag sealer machines are versatile tools that can be used for a variety of products, from food and pharmaceuticals to industrial goods. They can handle different types of packaging materials, including plastic, foil, and laminates, making them suitable for various industries.

Types of Bag Sealer Machines

Choosing the right bag sealer machine starts with understanding the different types available on the market. Each type is designed for specific packaging needs and production volumes, so it’s essential to choose one that aligns with your requirements.

1. Impulse Sealers

Impulse sealers are one of the most common types of bag sealers. They use a heated wire to create a seal, and the heat is only applied when the machine is engaged, making them energy-efficient. These sealers are ideal for sealing bags made from thermoplastic materials such as polyethylene and polypropylene. Impulse sealers are available in various sizes, making them suitable for both small-scale and large-scale operations.

2. Constant Heat Sealers

Unlike impulse sealers, constant heat sealers maintain a continuous temperature, making them suitable for sealing thicker materials such as foil, Mylar, and laminated films. These sealers are often used in industrial settings where high production volumes require a consistent and strong seal. Constant heat sealers are ideal for packaging items that need an airtight seal, such as food and medical supplies.

3. Vacuum Sealers

Vacuum sealers remove air from the packaging before sealing it, creating a vacuum-sealed environment. This type of sealing is particularly useful for preserving perishable items like food, as it significantly extends shelf life by preventing oxidation and bacterial growth. Vacuum sealers are commonly used in the food industry, as well as for packaging sensitive electronic components.

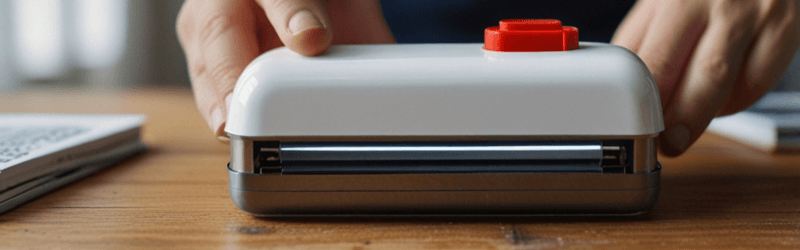

4. Handheld Bag Sealers

Handheld bag sealers are portable and easy to use, making them ideal for small businesses or home use. These sealers are typically used for light-duty sealing tasks and are perfect for sealing snack bags, coffee pouches, and other small items. While they may not offer the same level of efficiency as larger machines, handheld sealers are convenient for low-volume packaging needs.

The rechargeable portable sealer is very suitable for home use. It can seal unfinished snack bags, and can also seal bread bags so that they will not have odors after being placed in the refrigerator. It is easy to carry and can be carried with you.

5. Band Sealers

Band sealers are designed for continuous, high-speed sealing of bags and pouches. These machines use a conveyor belt to feed the bags through the sealing mechanism, making them ideal for high-volume production lines. Band sealers are versatile and can handle various materials and bag sizes, making them suitable for a wide range of industries.

6. Foot Pedal Sealers

Foot pedal sealers, also known as foot-operated sealers, allow the operator to control the sealing process with a foot pedal. This hands-free operation is ideal for sealing large or heavy bags that require both hands to position. Foot pedal sealers are commonly used in industries where consistent, high-quality seals are needed.

Factors to Consider When Choosing a Bag Sealer Machine

When selecting a bag sealer machine, several factors should be considered to ensure that you choose the right one for your packaging needs.

1. Type of Material to Be Sealed

The type of material you’re sealing is one of the most critical factors to consider. Different materials require different sealing mechanisms. For example, thin plastic bags work well with impulse sealers, while thicker materials like Mylar or foil might need a constant heat sealer. Understanding the material you’ll be working with will help you choose the appropriate machine.

2. Production Volume

Consider your production volume when choosing a bag sealer machine. If you’re running a small operation with low-volume needs, a handheld or foot pedal sealer might suffice. However, for high-volume production, a band sealer or an automated system may be more appropriate, as they can handle continuous sealing with minimal downtime.

3. Seal Strength and Quality

The strength and quality of the seal are crucial, especially for products that need to be protected from air, moisture, or contaminants. Choose a machine that offers a strong and consistent seal. This is particularly important for food packaging and pharmaceutical applications, where product integrity is paramount.

4. Ease of Use

The user-friendliness of the machine is another important consideration. Look for a bag sealer that is easy to operate, with intuitive controls and minimal setup required. This is especially important if the machine will be used by multiple operators or in a busy production environment.

5. Size and Portability

The size of the bag sealer machine should match your available workspace. For businesses with limited space, a compact or handheld sealer may be ideal. If portability is a concern, consider a lightweight machine that can be easily moved as needed.

6. Maintenance and Durability

Investing in a durable machine that requires minimal maintenance will save you time and money in the long run. Look for sealers made from high-quality materials like stainless steel and those that come with easy-to-replace parts. Regular maintenance is key to extending the life of your bag sealer, so choose a model that is easy to clean and maintain.

7. Budget

Your budget will also play a significant role in your decision. While it may be tempting to opt for a cheaper machine, remember that you often get what you pay for. Investing in a higher-quality machine might be more cost-effective in the long run, especially if it offers better performance, durability, and efficiency.

Understanding the Different Sealing Methods

Different bag sealer machines use various sealing methods, each with its own advantages. Understanding these methods will help you choose the right machine for your needs.

1. Heat Sealing

Heat sealing is the most common method used in bag sealers. It involves applying heat to the material to melt and bond it together. There are two primary types of heat sealing: impulse and constant heat. Impulse sealing uses short bursts of heat, making it energy-efficient, while constant heat sealing maintains a continuous temperature, ideal for thicker materials.

2. Vacuum Sealing

Vacuum sealing removes air from the bag before sealing it, creating a vacuum. This method is commonly used for food preservation, as it significantly extends shelf life by preventing spoilage. Vacuum sealing is also used in industrial applications where moisture or air can damage the product.

3. Ultrasonic Sealing

Ultrasonic sealing uses high-frequency vibrations to create friction and generate heat, bonding the material together without applying external heat. This method is ideal for materials sensitive to heat and is commonly used in medical and pharmaceutical packaging.

4. Thermoplastic Sealing

Thermoplastic sealing is used for materials that can be melted and re-bonded, such as polyethylene and polypropylene. This method is typically employed in impulse sealers and is suitable for creating strong, airtight seals.

Popular Brands and Models of Bag Sealer Machines

1. Uline Impulse Sealers

Uline is known for its high-quality impulse sealers that are ideal for sealing thermoplastic materials. These machines are available in various sizes and offer adjustable sealing times to accommodate different thicknesses.

2. FoodSaver Vacuum Sealer

FoodSaver is a leading brand in vacuum sealing, offering machines that are perfect for preserving food at home or in commercial kitchens. Their vacuum sealers are known for their ease of use, durability, and strong seals.

3. Weston Pro-2300 Commercial Grade Vacuum Sealer

The Weston Pro-2300 is a commercial-grade vacuum sealer designed for heavy-duty use.

It features a powerful motor, extra-wide sealing strip, and a durable stainless steel body, making it ideal for businesses that require high-volume vacuum sealing. The machine also offers adjustable seal times, ensuring that you can create a strong, airtight seal for a variety of bag materials.

4. AIE Constant Heat Sealers

AIE (American International Electric) is a trusted brand known for its reliable constant heat sealers. These machines are perfect for sealing thicker materials like Mylar, foil, and laminated bags. AIE sealers are designed for heavy-duty use, with features like adjustable temperature controls and sturdy construction to ensure consistent performance.

5. Waring Commercial WSG30 Handheld Bag Sealer

Waring is a reputable brand in the kitchen appliance industry, and their WSG30 handheld bag sealer is a great choice for small businesses or home use. It is portable, easy to use, and ideal for sealing small to medium-sized bags. This sealer is perfect for those who need a compact and affordable solution for light-duty packaging.

Maintenance and Troubleshooting Tips for Bag Sealer Machines

Proper maintenance of your bag sealer machine is essential to ensure its longevity and consistent performance. Here are some maintenance and troubleshooting tips:

1. Regular Cleaning

After each use, make sure to clean the sealing surface to remove any residue or debris that could affect the seal quality. For impulse and constant heat sealers, this may involve wiping down the heating element with a damp cloth. For vacuum sealers, it’s important to clean the sealing bar and vacuum chamber regularly to prevent build-up that could impede sealing.

2. Check for Wear and Tear

Regularly inspect your bag sealer machine for signs of wear and tear, such as frayed wires, worn-out sealing strips, or loose connections. Replacing worn parts promptly can prevent larger issues and extend the life of your machine.

3. Calibrate Temperature Settings

If you notice that the seals are not holding or are too weak, it might be due to incorrect temperature settings. Re-calibrate the machine according to the manufacturer’s instructions to ensure optimal sealing conditions.

4. Test Seals Regularly

To ensure the machine is functioning correctly, test the seals on a regular basis. Seal a test bag and check for uniformity and strength. If the seal is uneven or weak, it may indicate that the machine needs maintenance or repair.

5. Troubleshooting Common Issues

– Weak Seals: This could be due to low temperature settings or worn-out sealing strips. Increase the temperature or replace the strips as needed.

– Seal Not Holding: If the seal is not holding, check for contamination on the sealing surface or damaged bag material.

– Machine Not Heating: This may be due to electrical issues or a malfunctioning heating element. In this case, consult the user manual or contact customer support for assistance.

Where to Buy Bag Sealer Machines

Finding the right place to purchase a bag sealer machine can impact both the price and the quality of your purchase. Here are some options to consider:

1. Online Retailers

Websites like Amazon, eBay, and Alibaba offer a wide range of bag sealer machines, from budget-friendly options to high-end models. Online retailers often provide customer reviews, which can be helpful in making an informed decision.

2. Specialty Packaging Equipment Suppliers

For more specialized needs, consider purchasing from a packaging equipment supplier like Uline, Sealer Sales, or Heat Seal. These companies often provide a broader selection of machines, as well as expert advice and support.

3. Manufacturer Websites

Buying directly from the manufacturer can ensure that you are getting a genuine product with full warranty coverage. Manufacturers may also offer exclusive models and customer support services that are not available through third-party retailers.

4. Local Distributors

If you prefer to see the product in person before purchasing, local distributors or kitchen supply stores might carry the bag sealer machines you need. This option allows you to ask questions and get hands-on experience with the equipment.

Comparing Prices and Features of Bag Sealer Machines

When comparing bag sealer machines, it’s essential to look beyond just the price. Consider the features, warranty, and support options provided by each model. A higher upfront cost might be worth it if the machine offers better durability, efficiency, and ease of use.

– Impulse Sealers: Prices range from $20 to $200 depending on the size and features.

– Vacuum Sealers: Prices can range from $50 for basic models to $500 or more for commercial-grade units.

– Constant Heat Sealers: These typically range from $150 to $400, with industrial models costing even more.

– Handheld Sealers: These are usually the most affordable, ranging from $10 to $50.

When comparing models, also consider the cost of replacement parts, ease of maintenance, and the availability of customer support.

Conclusion: Why the Right Bag Sealer Machine is Essential for Your Packaging Needs

Choosing the right bag sealer machine is a critical decision that can significantly impact your packaging efficiency, product quality, and overall business success. Whether you’re sealing food, pharmaceuticals, or industrial products, the right machine will help you achieve strong, consistent seals that protect your products and enhance their shelf life.

Unfinished fruits., such as cherries, can be sealed with a sealing machine, and then they can be stored for a long time. When needed, such as for cherry juice, they will be fresher when taken out.

By considering factors like the type of material, production volume, seal quality, and ease of use, you can select a machine that meets your specific needs. With the right bag sealer, you can streamline your packaging process, reduce costs, and ensure that your products are securely sealed every time.

Invest in a high-quality bag sealer machine today, and take your packaging operation to the next level.